Maintenance management in organizations is one of the most difficult to manage both at technical and budgetary level, between a greater number of assets with a longer duration of its useful life, corrective maintenance or repair work are increasingly complex, more expensive and more frequent, the head of maintenance becomes a juggler between having fewer failures, higher availability and have the equipment 100% operational, among other efforts such as keeping inventories up to date, at appropriate levels, at the right cost, leading the area of health and safety, reviewing procedures, supervising them, managing maintenance suppliers, equipment and tool suppliers, ensuring that services are provided within the required standards, that the parts sent for repair arrive in good condition, additionally managing the staff, their complaints, their work style, considering whether there is a high or low number of staff, choosing among all the jobs which ones are for now or for later, or if they are all for now, assigning them to the available technicians, if it is known which ones are available, if they are busy reassign them to the urgent job.

Continuing, the maintenance manager must ensure that the equipment that is sent to where customers, leave in excellent condition, repaired, functional, complete, with all the complete third parts that accompany the asset, sometimes managing logistics, requesting vehicles, reviewing documents, loading equipment, parts and supplies, dispatching them, verify that they arrive on time to customer facilities, in turn supervising the maintenance tasks where the clients, that the technicians request the spare parts and tools that are, in the necessary quantity, that the jobs are done on time, that the scheduled jobs are done, that no mistakes are made, that all paper documentation is sent complete, that the technicians return the tools complete and in good condition.

In short, the list of responsibilities of a maintenance manager, maintenance scheduler, analysts, engineers, technicians is almost endless and the manager must also know about mechanics, electricity, welding, plumbing and others required by the nature of the business of the organization, the multitude of functions, knowledge and tasks makes that at some point things go out of control and organization, especially in the peaks of work, turning the area and the staff in firefighting mode, The multitude of functions, knowledge and tasks makes that at some point things get out of control and organization, especially in the peaks of work, turning the area and the staff in firefighting mode, the events are happening one after another, PQR’s one after another and task planning is configured in a way as Steven Covey says in his book, everything becomes important and urgent, in order of arrival in the e-mail..

What happens when the area is in firefighting mode?

The fire fighting mode is an indicator of the lack, weakness or lack of alignment of the maintenance strategy, this causes the following situations:

- Bad image of the area: the area takes a negative visibility both internally and externally of the company, the number of complaints from customers is increasing, due to lack of planning and proper coordination of maintenance tasks, preventive maintenance is postponed from one asset to another by the effect of attending a high incidence of important urgent work, the little or no functionality of the assets in the customer’s facilities is detrimental to the operational excellence of service, impoverishing the image and feeding the negative voice to voice and its reputation in detriment. Internally, management is putting the area under pressure, requesting full availability, affecting the vertical relations of the area towards the operations and general management of the company.

- Increased costs: costs in fire extinguishing mode inevitably go up, supply times are demanded shorter and shorter and therefore sales prices are increased by handling suppliers in that mode, they take advantage of the situation by knowing their customers very well, to avoid this the organization could maintain high cost high stocks, another factor that is taken into account is that to comply maintenance services must be requested to third parties to meet the requirements of process, customers and deliveries, well known that these external maintenance costs would be higher as perform them in-house. The work outside working hours and on weekends is increasing without control, the only important thing is to comply, that is to be effective but with an inefficient management, reducing the effectiveness in the same way.

- Negative work environment: due to the stress of the work environment caused by the amount of urgent work, communication is rough, greatly damaging the relationships between team members, as well as downward communications from the top continue down to the bottom of the hierarchical pyramid, a negative work environment affects the performance of people, increasing the time of work and its final quality as the mind is scattered in various modes of achievement, increasing the gap for error, allocating it from one to another.

- Increased backlog: the accumulation of non-executable preventive, proactive and preventive maintenance work directly causes unnecessary wear to equipment, whether new or used, causing an increase in maintenance costs, a decrease in its useful life and a decrease in the recovery factor of the investment in assets by reducing their productivity, the rate of potential failures is increasing and the accumulation of these in the short term will inevitably become functional failures or unscheduled stops. (Failure Analysis: CMMShere – Root Cause Analysis in Maintenance Management)

How do I get to the Fire Fighting Mode?

Several situations lead to fire fighting mode in maintenance management, some of the most important of which are:

- Lack of strategy: the maintenance strategy is the basis of all management, a balance between the number of assets, their complexity, their criticality in a process or provision of a service, their useful life elapsed or to be elapsed and the cost control tactics of the entire company directly influence the establishment of the best maintenance strategy, the lack or incorrect alignment of this will directly influence the success or failure of the area.

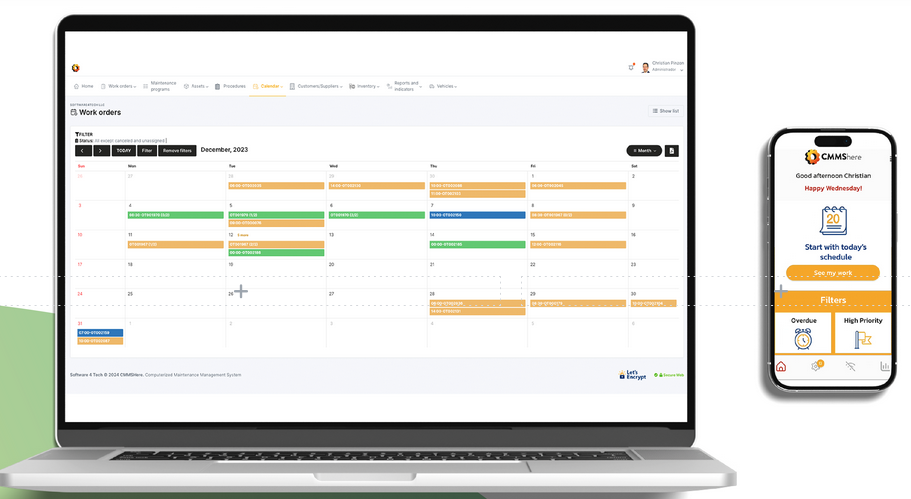

- Little or no systematization of management: the absence of a CMMS, a computerized maintenance management software and its relationship with the maintenance strategy will lead directly to fire fighting mode, current maintenance requires automation, the provision of adequate tools for the allocation of work orders, the measurement of the workload of the technical team and the availability of having centralized information in real time so that the CMMS becomes the best advisor, planner and means for maintenance managers and their technicians to ensure that the assets are fully operational at an adequate cost in the required time.

- Little or no management support: management must be fully aware that maintenance is the heart of the proper functioning of their company, constant support, the definition of achievable goals, the design and implementation of a realistic strategy and the establishment of economic means of help and personal assistance with reasonable returns on investment are essential so that the maintenance area does not go into firefighting mode.

- Lack of experience: the expertise of leadership and technical personnel is an influencing factor, the ability to manage the area in conjunction with the support of tools such as CMMShere, will allow the success of the operation, adequate work experience and in relation to the nature of the assets and their quantity will achieve that the processes are assorted with the required standards, The maintenance area is a big gear of many variables, which must be working together in the same frequency and aligned to move the machinery without alterations or deviations, when misalignment occurs, problems begin to appear that affect the final machinery. On the other hand of the skills required to perform in the maintenance area complements in great percentage to the maintenance profile, skills such as planning, problem solving, lateral thinking, ability to work under pressure to meet goals and analytical thinking are factors that do not conform a fire extinguishing mode of the maintenance area.

CMMShere as a tool to manage maintenance efficiently, quickly and easily.

CMMShere is a computerized maintenance management software, it has comprehensive tools that offer all the benefits that an effective maintenance area requires and that will allow the maintenance manager to:

- Perform maintenance tasks in the required time and quality.

- Perform a good job so that there are no problems with the customer due to equipment failures.

- Manage the personnel in an optimal way so that the works are executed in the established time.

- Proper management of the monthly maintenance budget.

- Avoid a high volume of corrective maintenance on equipment.

- Obtain high reliability and availability indicators.

- Manage the job well as maintenance manager to achieve good visibility from management, be seen as a competent professional.

- Meet the goals of equipment maintenance, so that when they are operating they do not fail and the customer is satisfied and there are no penalties.

- To achieve order and control in maintenance management.

- Perform the maintenance schedule in a timely and controlled manner according to the work order calendar in order to show leadership and productivity in the work.

- Perform the work during the company’s normal working hours and do not stay longer hours putting out fires, as this takes away family time.

- In the sector there is a lot of job uncertainty, feeling more entrenched in jobs.

- To be able to measure by indicators at the end of the month what is being done.

- Do not continue using macros or spreadsheets, or formats, or others, stop doing the same as always, as this is not giving the expected results in terms of achieving high levels of reliability, continue doing the same will not change the results..

- Reduce overall maintenance costs by 20% annually.

- To enable you to focus your efforts on organizing the maintenance process and have more time to manage it properly.

- If customers come in for an audit, they will leave convinced that they have selected the best supplier in the market..

- Receive prompt support and support to bring order to the maintenance organization, and additionally be able to train new technicians as they enter the company.

- Feel happy at work for receiving the benefits of changing the whole maintenance process, modernizing it and thus obtaining better results.

I would like to receive information about CMMShere

We have professionals around the world to provide support, training and constant accompaniment in the software implementation process, in the same way our support staff is available 24/7 for support in maintenance operations involving CMMShere and on the other hand in our blog you can read articles and download e-books with maintenance topics of interest, to contact us you can click here: Contact us or also consult our chatbot at any time.

No comment yet, add your voice below!