Maintenance Management in Spreadsheets. It Doesn't Get You Anywhere.

Spreadsheets have been a fundamental tool for managing various business processes, both in execution and monitoring. Within these processes, we can find the maintenance area, which is a critical process due to the responsibilities it entails, such as ensuring the operation of assets, meeting production goals, and providing services that meet customer expectations, among others. This makes maintenance a key part of the value chain offered to the target market. For this reason, maintenance management should be included, measured, and improved within the strategic plan of organizations, directly related to the areas responsible for generating the economic results of a company.

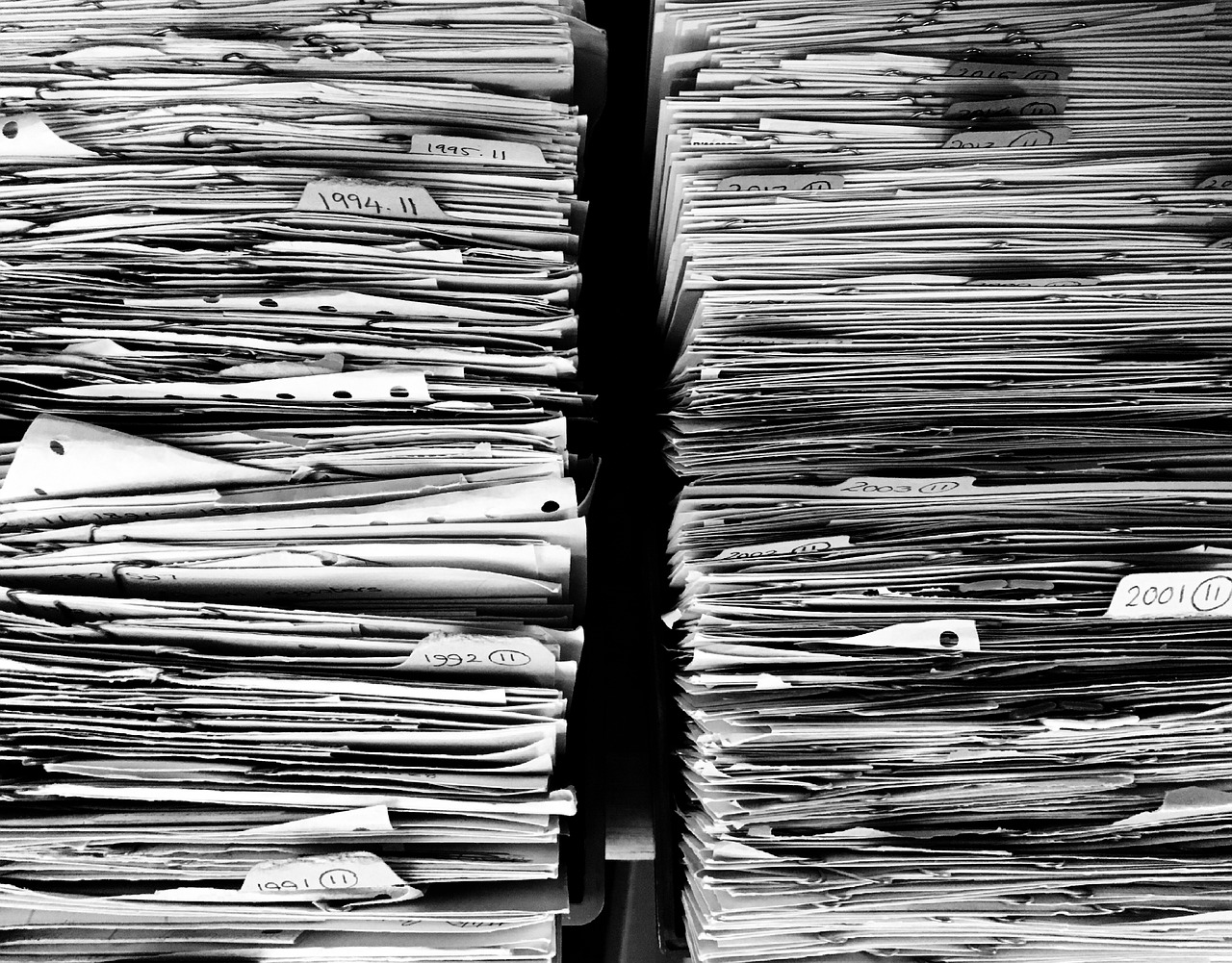

Macros created with spreadsheets were widely used in maintenance in the late nineties and the first decade of the two thousands across all types of organizations, as an excellent IT solution to market requirements, aligned with the strategic and organizational style of companies at that time. To achieve good results, these always needed to be accompanied by hundreds or thousands of hard copies, photographs, and physical folders used in the form of templates in word processors, becoming the support for what is done within the spreadsheets. This grew over time in direct proportion to the increase in the number of assets, the number of clients, revenues, and operational quality requirements increasingly demanded by end users, making storage more difficult both in terms of space and the ability to track the various situations that arise daily, especially in preventive maintenance tasks.

All Maintenance Management is Manual in Spreadsheets.

Although seemingly the spreadsheet, however one wants to view it, is a kind of automation of maintenance management, it really is not. What it is, is a very good way to store data, especially numerical data, and to turn it into totalizable and graphable results. The data is easy to find, filter, process, analyze, and has many more characteristics typical of this type of software.

For the process to be complete, in quotes, the macro requires other supports, such as filling out work order forms in word processors manually. The user must define multiple pieces of information in these, such as a tracking number given by the macro, names of those responsible for the task without knowing if they are busy with other tasks or not, determining what type of maintenance process flow applies to the work order, changing it, modifying it, or creating a new one if needed, checking if there are spare parts and supplies either in the macro without knowing if it is updated or not, or going to the warehouse to ask about availability. If they are not available, the entire procurement process must take place outside the macro environment. Additionally, tools must be assigned without knowing if they are available or not, if they have been lost, or if they need to be decommissioned because they no longer have full functionality. After all the time spent defining the work order format, it is printed, handed over to the maintenance technician, or sent to their email.

The technician takes the form and can take two paths for execution. In one, they print it out and begin to perform the work, filling it out by hand, writing down all the activities carried out on the asset. The work is done in a time that may or may not be real; if they do not complete the work for any reason, they leave the form in the asset’s folder and start another preventive maintenance task. They may forget the previous task or begin to perform other sequential tasks, easily losing control and order. In the second path, the technician can take a laptop to the work site, in an environment or location that is difficult to access. They fill out the form, insert the necessary photographs into the document, and finally convert it to PDF, sending it via email to the maintenance manager. It is uncertain when the email will be read due to the numerous emails arriving regarding work orders. If additional work on the asset needs to be done, it will be postponed until the tasks required are gathered and discussed to start the work again. All this documentation is generally managed in various ways across multiple sources, whether in email, opening folders in the file manager, printing the filled-out forms and placing them in A to Z folders, or making changes in the macro to update the information. All these processes require a lot of administrative time that could be spent on quality operational time, which would allow for order and control in maintenance management.

Corrective Maintenance Management is Difficult in Spreadsheets.

When unplanned downtimes occur in assets that require immediate repair or corrective maintenance, controlling them, tracking them properly, and correcting failure states using spreadsheets becomes difficult. The asset’s history must be consulted manually, searching either in physical folders or in the information stored on the computer for all maintenance reports, reading each one until past failures of the asset are found to conduct the respective analyses to determine whether there are design flaws, installation issues, operational conditions, poor quality of supplies or spare parts, or other reasons. Then, the equipment dossier must be sought, and manuals, procedures, and other recommendations defined by the manufacturer must be reviewed to finally identify the origin of the failure after much analysis.

Corrective maintenance is very frequent, and tracking it through spreadsheets becomes a very cumbersome process, to the point that the area turns into a fire-fighting environment, as macros do not have the capability to automate measurement processes, especially concerning times. The measurement of MTBF requires availability times, and this can be done imprecisely and somewhat complicated in macros. A similar but slightly less complex situation occurs with MTTR. Both indicators allow for the calculation of the asset’s reliability, but real indicators would not be obtained to make informed decisions focused on availability and cost reduction.

Productivity and Team Communication are the Most Important.

The processing, analysis, and management of information are becoming increasingly complex due to the growing and vast amount of information available from various dispersed sources and the difficulty in tracking it. This negatively impacts planning, coordination, resource availability, and therefore the costs of the area, as there is no capacity to make timely decisions based on accurate data, low visibility of tasks, low efficiency in management, and no real-time update capability in maintenance management.

The maintenance area is managed as a collaborative process of constant communication, where information is continuously exchanged among team members. Work order assignments should be automated and in real-time, changes in scheduling must be made easily and immediately, and the technical workload must be known to avoid burnout or overstaffing. Inspection events should be communicated based on a single premise and in real-time, and all maintenance management activities should be executed well within working hours, creating a good work environment with constant communication. These characteristics are far from being achieved even with the most structured spreadsheet macros; these required capabilities cannot and will not be met by this type of software.

Another factor in the communication of the area is mobility. Technicians must move around various locations within the plant, maintenance workshop, or difficult-to-access areas, or externally to nearby or remote locations where they have their assets serving clients or maintaining the equipment entrusted to their care. For this type of work, the use of smartphones or tablets, with or without internet, is essential for easily and efficiently completing tasks and timely communicating events found in the assets to provide expected service and differentiate themselves from the competition. The functionality of spreadsheets on smartphones or tablets is not very visible, complicated, and difficult to manage due to their interface; the software is not designed for these features and, in a way, is not applicable for such tasks.

What is a CMMS or Computerized Maintenance Management System?

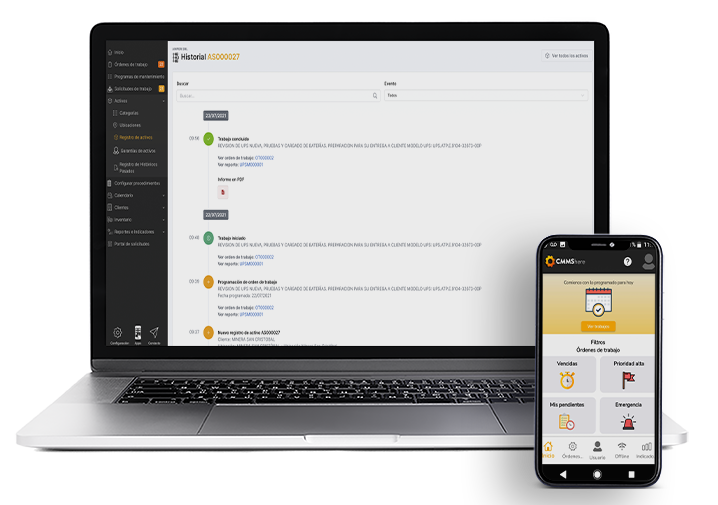

A CMMS (acronym for Computerized Maintenance Management System) is maintenance management software that allows organizations to be productive, efficient, and strategic when managing their maintenance in a controlled and organized manner. It enables efficient and effective time management so that maintenance teams can work in a coordinated and well-planned way, making effective use of available resources in inventory. At the same time, area leaders can have a comprehensive view of their management through a single interface, measuring indicators that show the level of learning and achievement of goals.

Technical personnel will be able to receive real-time notifications via mobile app, WhatsApp, and email for preventive or corrective maintenance work orders, complete work orders easily and dynamically, and generate customized reports with valuable information, making their maintenance work much more professional.

Is CMMS the Solution to Maintenance Management in Excel Spreadsheets?

Yes, CMMSHere is the new way to manage maintenance in organizations across various productive sectors, easily scalable from having one user with a single asset to over 100 users and more than 1,000 assets. The software has the most modern capabilities and applications in the industry, being the most customizable product on the market and with costs adjustable to the size of any organization. It has the full potential to manage maintenance in real-time, with access to any type of information at any moment, making it easy to consult histories and analyze failures.

CMMSHere is mobile with both OFFLINE and ONLINE capabilities, featuring the latest technology in predictive maintenance monitoring supported by communication and IoT (Internet of Things) devices from Industry 4.0, allowing constant control of operational condition variables for those assets classified as critical.

1 Comment

Fantastic goods from you, man. I’ve understand your stuff previous to and

you’re just too magnificent. I really like what you have acquired here, certainly like what you are saying and the way in which you say it.

You make it enjoyable and you still care for to keep it smart.

I cant wait to read far more from you. This is actually a tremendous website.